- We design ventilation solutions based on in-depth aeraulic studies and on-farm tests, to optimise air flows whatever the configuration of the livestock buildings, the method of control, the type of production and their geographical location.

- We design mechanical parts and sub-assemblies, including the use of a wide range of materials (metal, plastic, composite, etc.).

- We ensure compliance with mechanical and environmental constraints, to guarantee operation in an agricultural environment.

Mechanical development

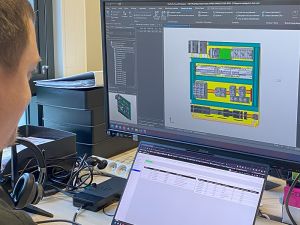

Electronic development

- We develop our own electronic boards, as well as the associated programming, to ensure the right fit with environmental requirements and constraints.

- We then oversee our sub-contractors for the board production process, constantly striving to optimise operation and reliability.

IT development

- Our teams work with farmers and installers to convert their business requirements into specific software and applications that we embed in the controllers.

- We are committed to continuous improvement and use advanced design methods to ensure that new developments are made available to our customers quickly and reliably.

- We also manage the MyTR Cloud platform and the secure, optimised data storage, so that your data can be used whenever you need it.

- We are constantly improving the user interface to make our products easier to learn and use.

Tests and validation for products/design concepts

All our products are extensively tested before being made available to customers:

- Either through in-house testing or at our suppliers

- For some products, these tests are accompanied by tests in external laboratories

- Field tests with partner livestock farmers to ensure reliability in customer environments

Electrical development

- Our development team designs specific electrical cabinets, tailored to our customer’s requirements

- It produces all the wiring diagrams and optimises the space required in the electrical cabinets, to guarantee trouble-free operation and maintenance

- It monitors and implements all regulatory constraints

Product Industrialisation

- To ensure that products are perfectly completed in production, the team establishes the best possible assembly methods

- The ongoing quest to optimise manufacturing means that we can aim to harmonise production and achieve optimum quality, while ensuring ease of maintenance after installation, in particular through precise identification of the integrated components

- As we are always on the lookout for ways to improve, we regularly incorporate additional features based on feedback from breeders and installers